Increased productivity and respect for foodstuffs

Separation of different ingredients by the DESTEMMER AND SORTER means compacted foods can be kept whole, while gently and precisely separating them.

"This innovation improves the productivity of food processing industries"

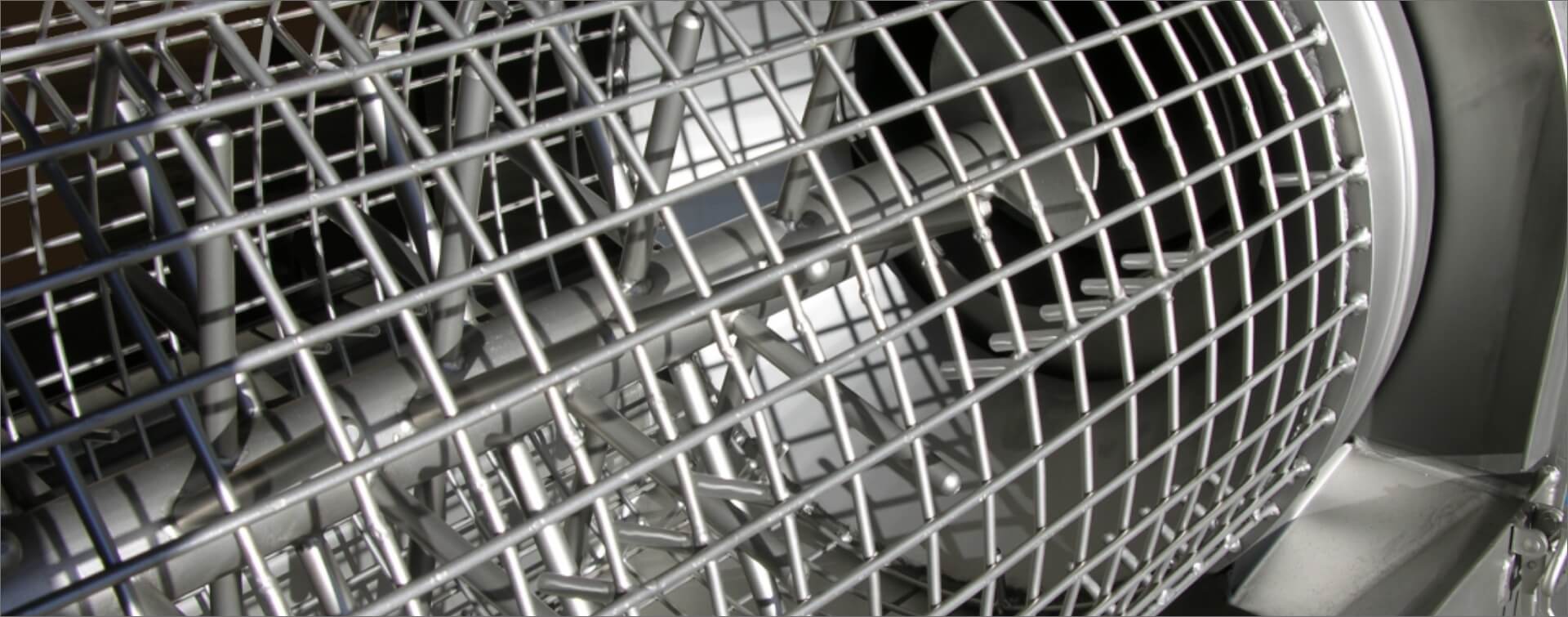

The DESTEMMER AND SORTER comprises mainly a horizontal cylindrical grid made up of crossed bars and a hedgehog-shaped tree in the centre of the grid, both separately motorised, turning in the same direction but at different speeds.

Packs are introduced into the entry duct then coarsely crushed by an Archimedes screw when they are transferred to the cylindrical grid. These portions of blocks are picked up by the fingers of the cylinder combs, the speed of which has been calculated so that they break away in the upper part of the grid on the vertical part of the hedgehog. It is when they come into contact with the fingers of the hedgehog, totally weightlessly, that they undergo a sudden acceleration (x3) which separates them from each other without damaging them.

The machine is fully covered and secured in line with France's AAA industry norms, facilitating maintenance and fast, simple cleaning.

IQF ingredients

Use of IQF (Individual Quick Frozen) means each item can be frozen separately just after the food cutting phase. This ensures high microbiological quality and optimal preservation of flavour, nutritional value and texture of the food, which is ready to be mixed after this process. This system means that the ice crystals that form in tissue cells are much smaller, which avoids breakage of the cell walls that make up the tissues of meat. So when foods are thawed, there is no fluid flow and all the properties are retained, like those of a recently-formed product. This technology is applicable not only for fruit and vegetables, but also for meat, seafood and cheese.

Productivity increases and respect for food

Separating frozen, lumpy or agglomerated foods without thawing or processing and quasi-instantaneously means a significant increase in productivity and ensures high sanitary quality is maintained. It therefore also means all the assets of IQF products are retained plus optimal preservation of flavour, nutritional value and texture of the food.

For all specific requirements, please get in touch, and our teams will advise and assist you to improve your productivity on a daily basis, as well as your capacity for development and the quality of your output with total safety.

CONTACT USDestemming raw and cooked IQF onions

Destemming IQF scallops

Destemming diced mango