EGRETIER PIG cleaning

PIG CLEANING / CLEANING IN PLACE (CIP)

Our food transfer lines are fitted with pipework PIGGING and cleaning-in-place (CIP) systems.

PIGGING

The entire scraping system is supervised by a PLC that takes into account the detection and speed of the PIG. Operation is carried out by electromagnetic valves in a stainless steel box. The pushing movement is done with compressed air or water.

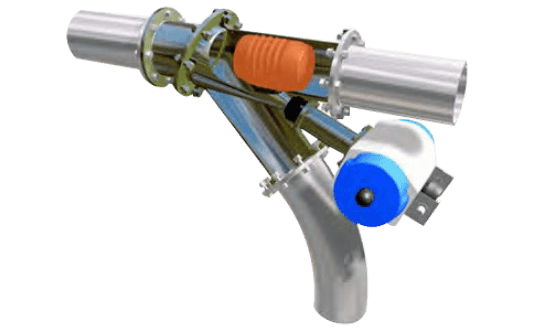

The two-way cone valve is used as it is designed to receive a secured PIG station allowing either the whole product for transfer or the PIG to pass through, in total safety

In the case of PIG firing, a specified quantity of compressed air enables the PIG to leave its station and reach its arrival point, called the PIG STOP valve. Then a GUILLOTINE valve located above the PIG STOP valve closes the transfer path to enable the PIG to automatically return to its original station, through the same pneumatic process, therefore ensuring a thorough cleaning process in both directions in as short a time as possible

In addition, EGRETIER's two-way valve means SCRAPING can take place at several contact points, whenever the operator wishes to do so

PIG stopped mechanically or automatically with return system and cleaning in place programming

EGRETIER's two-way cone valve with cleaning PIG

This automatic cleaning system without disassembly is integrated into our transfer lines or storage silos during their design. Tanks, pipes or other fitted machines are washed using a parallel water circuit. The operator can program different cycles with washing and rinsing products, according to the specifications.

TRANSFER OPERATION AND SCRAPING WITH PIG

Meets all food processing industry hygiene requirements.

For all specific requirements, please get in touch, and our teams will advise and guide you to improve your productivity, your capacity for expansion and the quality of your output on a daily basis.