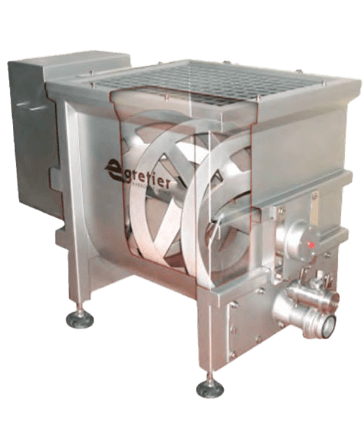

EGRETIER's double-ribbon mixer

This CONCENTRIC DOUBLE-RIBBON horizontal mixer is specially designed to improve the mixing of delicate and heterogeneous ingredients according to structure, density and difference in volume.

It combines the work of a double coil, ie. the inner belt ensures ingredients are thoroughly mixed in one direction, while the entire bottom of the mixer is scraped by the outer ribbon. This double concentric ribbon also makes it possible to very quickly empty the entire product simply by reversing the direction of rotation.

In addition, this mixer offers the possibility of integrating a volumetric pump, which deals with transfer of the preparation to the batching and packaging unit.

This type of mixer is particularly suitable for preparations of components with sauces or emulsions, for example:

•Raw or cooked meat,

•Ragouts, risottos,

•Vegetables such as celery, plus mayonnaise or ratatouille,

•Fish such as soup or seafood rillettes,

•Patés such as corned beef etc.

The benefits are reduced time and mixing efficiency, while preserving the integrity of the blended products.

•316L stainless steel

•Double jacketed

•Waterproof hood

•Vacuum

•CO2 or steam injection

•Weighing system

•Cleaning in place

•Cleaning balls

•Europe tank guide device and safety grid

•Fixed and swivel wheels

•PLC control

•Level and temperature probe

•Self-emptying by external connection, by screw,

or by incorporated volumetric pump.

•Capacity from 100 to 6000 liters

•304 or 316L stainless steel construction

IQF product mix

Meets all food processing industry hygiene requirements.

For all specific requirements, please get in touch, and our teams will advise and guide you to improve your productivity, your capacity for expansion and the quality of your output on a daily basis.